New Projects

TITANO™ - THE OGIVAL FENDER

A great revolution in the defence of quays and a real alternative to usual fenders. TITANO™ is a new patent fender, innovative in design, performance and docking logic. TITANO™is safer and faster docking compared to other fenders, avoiding cable stranding problems.

|

TECHNICAL CHARACTERISTICS: DIMENSION: (as a part)

|

Density (Hardness): |

Windmill DP2 Offshore Installer

|

Classification: Purpose: Dimensions: Accommodation: |

Diesel Electric System: Electric Power Plant: Dynamic Postion System: Windmill Capacity: |

550 Ton Deepwater Flexible Cable Lay DP3 (Conversion Project)

|

Dimensions: |

Accommodation: Type: |

550 Ton Deepwater Flexible Cable Lay DP3 (Conversion Project) |

550 Ton Deepwater Flexible Cable Lay DP3 (Conversion Project) |

Offshore Support Vessels that use liquefied gas (LNG) as fuel.

In order to meet the environmental present sound and help ship-owners, and cutting the costs - EASTPROJECT is expanding its offering projects in offshore support vessel that use liquefied gas (LNG) as fuel.

Since 2007, Eastproject engineering innovation team , turned its focus to tugs and supply vessels fuelled with LNG and bi-fuel. Since the largest portion of vessel emissions is responsible of pollution in harbour zones and ports, the environmental concern is presently increasing very fast.

Many people think that tugs help bigger ships in and out port, there are many class of tugs with different characteristics small, easily-manoeuvrable harbour tugs to large ocean-going vessels.

After a full review of tug operations, Eastproject decided to concentrate on escort tug 32 to 36 m length and supply vessel DP2 class abt 70 m.

On tugs , using LNG fuel , technically for consumption and emissions , the diesel electric solution is the best for all technical involvements:

- location of LNG storage

- reduction of the emission in the diesel electric compare to the traditional shafts.

The project regarding East project's LNG tugs take into account even the future solution of hybrid and necessary spaces for the future installation of batteries.

LNG FUELLED FERRY

We've also developed LNG ferries for Mediterranean, but also in other ships that use LNG and/or dual fuel.

By employing natural gas as fuel, the potential pollution to water and harmful exhaust emissions could be substantially reduced, making the water bound transportation even more environmentally friendly.

This paper is dealing with the technical challenges and the safety aspects related to introducing natural gas as fuel in passenger ships.

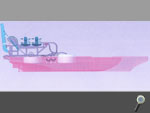

INNOVATIVE TECHNOLOGIES - PIPELAY HOVERBARGE DEVELOPMENT

In the last six years, Eastproject has studied the shallow water operation aspects of the North Caspian Sea and shallow water mouth river and bush environment gas and oil operation, researching equipment capable to work with a very low draft.

Based on its findings, Eastproject has developed all operational spread aspects on air cushion support barge concept.

Using Hovertran‘s existing air cushion technology Eastproject is able to complete the air cushion platform to lay steel pipes and flexible hoses with a considerably daily production

Eastproject has also studied all support spread manoeuvering, like hover barge feeders, accommodation compound, piling and floating mooring spread, drilling platform, in very shallow water and swamp conditions that no other equipment can cover .